Aluminum Angle Berm Specifications

Durable Spill Berms for Effective Containment

Easy Setup and Installation

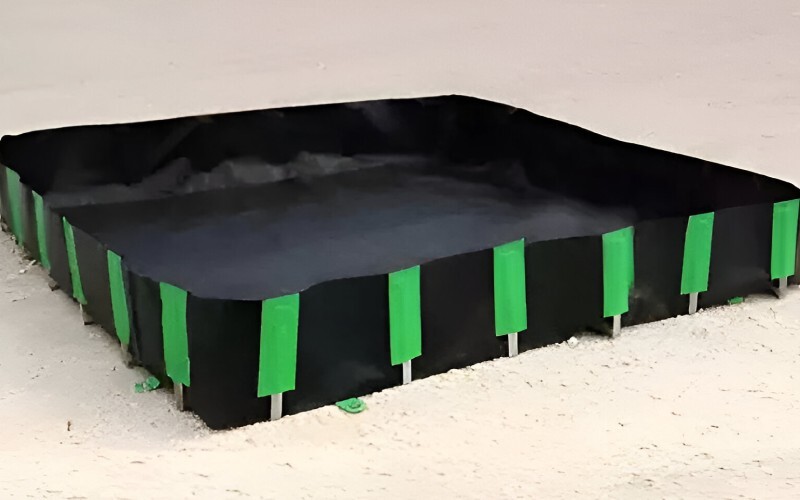

Our durable spill berms are meticulously engineered for the effective containment of hazardous materials, ensuring robust protection across various industrial applications. Constructed from high-quality, industrial-strength materials, these spill berms provide exceptional resistance to a wide range of chemicals and hazardous substances.

Explore the sizes we offer for our aluminum angle berms. We have a variety of options tailored to meet different applications.

Looking for spill containment solutions? We can help! Call us at 1-863-270-8118 or contact us to discuss your needs.

Spill Berms Containment Details

Our durable spill berms are meticulously engineered to provide superior containment of hazardous materials across a wide range of industrial applications. Constructed from high-quality, industrial-strength materials, these berms offer exceptional chemical resistance and robust performance in the most demanding environments. The flexible design allows for easy customization to fit unique site requirements, ensuring a perfect fit every time. Whether deployed at industrial sites, construction areas, or for environmental protection, our spill berms are an ideal solution for effective spill control. Their quick and straightforward installation process minimizes downtime, while their durable construction ensures long-term reliability and compliance with stringent environmental and safety regulations. Trust our spill berms to provide the essential barrier needed to protect your site from spills and contamination.

With a focus on reliability and ease of use, our spill berms are designed to withstand extreme weather conditions, making them suitable for both hot and cold climates. The integrated drainage system effectively manages overflow and prevents water accumulation, maintaining the integrity of the containment area. These berms are portable and reusable, offering a cost-effective solution for spill containment and environmental protection. Whether you are addressing spill prevention, emergency response, or routine environmental protection, our spill berms provide the high-quality and dependable performance you need. Contact us today at 1-863-270-8118 or request a quote to learn more about our spill berms and how they can meet your specific needs.

Explore our range of Secondary Containment Products for more containment options and solutions.

Features of Our Spill Berms

- Robust Construction: Made from high-grade, industrial-strength materials for enhanced durability and longevity.

- Easy Setup: Designed for quick and straightforward installation to minimize downtime.

- Chemical Resistance: Resistant to a wide range of chemicals and hazardous materials, ensuring reliable containment.

- Custom Sizes Available: Tailored to fit specific site requirements and dimensions for a perfect fit.

- Portable Design: Lightweight and easy to transport, allowing for versatile use across different locations.

- Weather Resistance: Capable of withstanding extreme weather conditions, making them suitable for both hot and cold climates.

- Integrated Drainage System: Effectively manages overflow and prevents water accumulation, maintaining the integrity of the containment area.

Benefits of Using Spill Berms

- Reliable Spill Containment: Provides effective containment of spills and leaks, ensuring environmental safety.

- Versatile Applications: Suitable for a variety of environments, including industrial sites, construction areas, environmental protection efforts, and emergency response scenarios.

- Cost-Effective: Reduces potential cleanup costs and environmental fines, offering a cost-effective solution for spill management.

- Compliance: Helps meet regulatory requirements for spill containment and environmental safety, reducing legal liabilities.

- Reusable: Durable design allows for multiple uses, providing long-term value and sustainability.

- Enhanced Safety: Ensures a secure barrier to contain spills and prevent environmental contamination, enhancing overall site safety.

Aluminum Angle Spill Berm Specifications

| Part Number | Dimensions ft. (m) | Containment Capacity (gal) | Weight lbs. (kg) |

|---|---|---|---|

| Ultratech 8250 | 6 x 4 x 1 (1.8 x 1.2 x .3) | 179 | 21 (9.5) |

| Ultratech 8251 | 6 x 6 x 1 (1.8 x 1.8 x .3) | 269 | 26 (11.8) |

| Ultratech 8252 | 10 x 10 x 1 (3 x 3 x .3) | 748 | 52 (23.6) |

| Ultratech 8270 | 20 x 10 x 1 (6.1 x 3 x .3) | 1496 | 88 (39.9) |

| Ultratech 8271 | 30 x 10 x 1 (9.1 x 3 x .3) | 2244 | 124 (56.2) |

| Ultratech 8272 | 40 x 10 x 1 (12.2 x 3 x .3) | 2992 | 160 (72.6) |

| Ultratech 8273 | 50 x 10 x 1 (15.2 x 3 x .3) | 3740 | 196 (88.9) |

| Ultratech 8274 | 12 x 12 x 1 (3.7 x 3.7 x .3) | 1077 | 69 (31.3) |

| Ultratech 8275 | 20 x 12 x 1 (6.1 x 3.7 x .3) | 1795 | 102 (46.3) |

| Ultratech 8276 | 30 x 12 x 1 (9.1 x 3.7 x .3) | 2692 | 144 (65.3) |

| Ultratech 8277 | 40 x 12 x 1 (12.2 x 3.7 x .3) | 3590 | 185 (83.9) |

| Ultratech 8278 | 50 x 12 x 1 (15.2 x 3.7 x .3) | 4488 | 227 (103) |

| Ultratech 8253 | 60 x 12 x 1 (18.3 x 3.7 x .3) | 5385 | 268 (121.6) |

| Ultratech 8279 | 15 x 15 x 1 (4.6 x 4.6 x .3) | 1683 | 95 (43.1) |

| Ultratech 8280 | 20 x 15 x 1 (6.1 x 4.6 x .3) | 2244 | 118 (53.5) |

| Ultratech 8281 | 30 x 15 x 1 (9.1 x 4.6 x .3) | 3366 | 165 (74.8) |

| Ultratech 8282 | 40 x 15 x 1 (12.2 x 4.6 x .3) | 4488 | 212 (96.2) |

| Ultratech 8254 | 50 x 15 x 1 (15.2 x 4.6 x .3) | 5610 | 259 (117.5) |

| Ultratech 8255 | 66 x 15 x 1 (20.1 x 4.6 x .3) | 7405 | 334 (151.5) |

Applications of Spill Berms

Our spill berms are versatile and suitable for a wide range of applications, providing reliable containment solutions across various industries:

- Industrial Sites: Ideal for containing spills of hazardous materials and chemicals in manufacturing plants, warehouses, and refineries.

- Construction Areas: Perfect for preventing contamination from fuel, oil, and other substances at construction sites.

- Environmental Protection: Used in environmental protection efforts to contain spills and prevent soil and water contamination.

- Emergency Response: Essential for quick deployment in emergency situations to contain accidental spills and leaks.

- Transportation: Utilized in transportation hubs and during the transport of hazardous materials to manage and contain potential spills.

- Agricultural Settings: Suitable for use in farms and agricultural operations to contain fertilizers, pesticides, and other chemicals.

- Mining Operations: Effective in containing spills in mining operations, protecting the surrounding environment from contamination.

Maintenance of Spill Berms

Proper maintenance of spill berms is crucial to ensure their longevity and effectiveness. Here are some guidelines for maintaining your spill berms:

- Regular Inspections:

- Conduct regular inspections to check for any signs of wear, damage, or deterioration.

- Look for punctures, tears, or weakened areas that could compromise the berm's integrity.

- Repairs:

- Promptly repair any damage using compatible repair kits or patches to maintain the berm's effectiveness.

- Ensure that repairs are thorough and that the berm is fully sealed to prevent leaks.

- Storage:

- Store berms in a cool, dry place when not in use to prevent UV damage and material degradation.

- Keep them away from sharp objects and extreme temperatures that could cause damage.

- Proper Handling:

- Handle berms with care during installation, transportation, and storage to avoid unnecessary wear and tear.

- Train personnel on the correct handling and setup procedures to minimize the risk of damage.

- Monitoring and Documentation:

- Maintain a log of inspections, cleanings, and repairs to track the condition of the berms over time.

- Regularly review maintenance records to identify patterns and address recurring issues.

Looking for spill containment solutions? We can help! Call us at 1-863-270-8118 or contact us to discuss your needs.